|

Reverted 1 edit by 209.206.25.191 (talk): Unsourced

|

|||

| (47 intermediate revisions by 16 users not shown) | |||

| Line 1: | Line 1: | ||

{{Short description|Electronic system that manages a rechargeable battery (cell or battery pack)}} |

{{Short description|Electronic system that manages a rechargeable battery (cell or battery pack)}}{{Refimprove|date=February 2024}} |

||

| ⚫ | |||

| ⚫ | A '''battery management system''' ('''BMS''') is any electronic system that manages a [[rechargeable battery]] ([[Electrochemical cell|cell]] or [[battery pack]]), such as by protecting the battery from operating outside its [[safe operating area]]{{clarify|the link currently goes to an article about semiconductor devices, not rechargeable batteries|date=May 2019}}, monitoring its state, calculating secondary data, reporting that data, controlling its environment, authenticating it and / or [[Battery balancing|balancing]] it.<ref>{{cite book|url=https://books.google.com/books?id=fGdklAEACAAJ|title=Battery Power Management for Portable Devices|isbn=9781608074914|last1=Barsukov|first1=Yevgen|last2=Qian|first2=Jinrong|date=May 2013}}</ref> |

||

| ⚫ | |||

| ⚫ | A '''battery management system''' ('''BMS''') is any electronic system that manages a [[rechargeable battery]] ([[Electrochemical cell|cell]] or [[battery pack]]), such as by protecting the battery from operating outside its [[safe operating area]]{{clarify|the link currently goes to an article about semiconductor devices, not rechargeable batteries|date=May 2019}}, monitoring its state, calculating secondary data, reporting that data, controlling its environment, authenticating it and / or [[Battery balancing|balancing]] it.<ref>{{cite book|url=https://books.google.com/books?id=fGdklAEACAAJ|title=Battery Power Management for Portable Devices|isbn=9781608074914|last1=Barsukov|first1=Yevgen|last2=Qian|first2=Jinrong|date=May 2013|publisher=Artech House }}</ref> |

||

'''Protection circuit module''' ('''PCM''') is a simpler alternative to BMS.<ref>{{cite web | title=PCM vs BMS, a dilemma for product designers | website=BMS PowerSafe® | date=2016-06-01 | url=https://bmspowersafe.com/en/technology-en/pcm/ | access-date=2024-03-21}}</ref> |

|||

A battery pack built together with a battery management system with an external communication [[Bus (computing)|data bus]] is a [[smart battery pack]]. A smart battery pack must be charged by a [[smart battery charger]].{{Citation needed|date=October 2017}} |

A battery pack built together with a battery management system with an external communication [[Bus (computing)|data bus]] is a [[smart battery pack]]. A smart battery pack must be charged by a [[smart battery charger]].{{Citation needed|date=October 2017}} |

||

| Line 21: | Line 22: | ||

* The BMS will also control the recharging of the battery by redirecting the recovered energy (i.e., from [[Regenerative brake|regenerative braking]]) back into the battery pack (typically composed of a number of battery modules, each composed of a number of cells). |

* The BMS will also control the recharging of the battery by redirecting the recovered energy (i.e., from [[Regenerative brake|regenerative braking]]) back into the battery pack (typically composed of a number of battery modules, each composed of a number of cells). |

||

Battery thermal management systems can be either passive or active, and the cooling medium can either be air, liquid, or some form of phase change. Air cooling is advantageous in its simplicity. Such systems can be passive, relying only on the convection of the surrounding air, or active, using fans for airflow. Commercially, the Honda Insight and Toyota Prius both use active air cooling of their battery systems.<ref>{{Cite journal|last1=Liu|first1=Huaqiang|last2=Wei|first2=Zhongbao|last3=He|first3=Weidong|last4=Zhao|first4=Jiyun|date=October 2017|title=Thermal issues about Li-ion batteries and recent progress in battery thermal management systems: A review|journal=Energy Conversion and Management|volume=150|pages=304–330|doi=10.1016/j.enconman.2017.08.016|issn=0196-8904}}</ref> The major disadvantage of air cooling is its inefficiency. Large amounts of power must be used to operate the cooling mechanism, far more than active liquid cooling.<ref name=":0">{{Cite journal|last1=Chen|first1=Dafen|last2=Jiang|first2=Jiuchun|last3=Kim|first3=Gi-Heon|last4=Yang|first4=Chuanbo|last5=Pesaran|first5=Ahmad|date=February 2016|title=Comparison of different cooling methods for lithium ion battery cells |journal=Applied Thermal Engineering|volume=94|pages=846–854|doi=10.1016/j.applthermaleng.2015.10.015|issn=1359-4311|doi-access=free}}</ref> The additional components of the cooling mechanism also add weight to the BMS, reducing the efficiency of batteries used for transportation. |

Battery thermal management systems can be either passive or active, and the cooling medium can either be air, liquid, or some form of phase change. Air cooling is advantageous in its simplicity. Such systems can be passive, relying only on the convection of the surrounding air, or active, using fans for airflow. Commercially, the Honda Insight and Toyota Prius both use active air cooling of their battery systems.<ref>{{Cite journal|last1=Liu|first1=Huaqiang|last2=Wei|first2=Zhongbao|last3=He|first3=Weidong|last4=Zhao|first4=Jiyun|date=October 2017|title=Thermal issues about Li-ion batteries and recent progress in battery thermal management systems: A review|journal=Energy Conversion and Management|volume=150|pages=304–330|doi=10.1016/j.enconman.2017.08.016|bibcode=2017ECM...150..304L |issn=0196-8904}}</ref> The major disadvantage of air cooling is its inefficiency. Large amounts of power must be used to operate the cooling mechanism, far more than active liquid cooling.<ref name=":0">{{Cite journal|last1=Chen|first1=Dafen|last2=Jiang|first2=Jiuchun|last3=Kim|first3=Gi-Heon|last4=Yang|first4=Chuanbo|last5=Pesaran|first5=Ahmad|date=February 2016|title=Comparison of different cooling methods for lithium ion battery cells |journal=Applied Thermal Engineering|volume=94|pages=846–854|doi=10.1016/j.applthermaleng.2015.10.015|issn=1359-4311|doi-access=free|bibcode=2016AppTE..94..846C }}</ref> The additional components of the cooling mechanism also add weight to the BMS, reducing the efficiency of batteries used for transportation. |

||

Liquid cooling has a higher natural cooling potential than air cooling as liquid coolants tend to have higher thermal conductivities than air. The batteries can either be directly submerged in the coolant or coolant can flow through the BMS without directly contacting the battery. Indirect cooling has the potential to create large thermal gradients across the BMS due to the increased length of the cooling channels. This can be reduced by pumping the coolant faster through the system, creating a tradeoff between pumping speed and thermal consistency.<ref name=":0" /> |

Liquid cooling has a higher natural cooling potential than air cooling as liquid coolants tend to have higher thermal conductivities than air. The batteries can either be directly submerged in the coolant or coolant can flow through the BMS without directly contacting the battery. Indirect cooling has the potential to create large thermal gradients across the BMS due to the increased length of the cooling channels. This can be reduced by pumping the coolant faster through the system, creating a tradeoff between pumping speed and thermal consistency.<ref name=":0" /> |

||

=== Computation === |

=== Computation === |

||

Additionally, a BMS may calculate values based on the |

Additionally, a BMS may calculate values based on the items listed below, such as:{{citation needed|date=May 2019}} |

||

* [[Voltage]]: minimum and maximum cell voltage |

* [[Voltage]]: minimum and maximum cell voltage |

||

* [[State of charge]] (SoC) or [[depth of discharge]] (DoD), to indicate the charge level of the battery |

* [[State of charge]] (SoC) or [[depth of discharge]] (DoD), to indicate the charge level of the battery |

||

* [[State of health]] (SoH), a variously defined measurement of the remaining capacity of the battery as |

* [[State of health]] (SoH), a variously defined measurement of the remaining capacity of the battery as a fraction of the original capacity |

||

* [[State of power]] (SoP), the amount of power available for a defined time interval given the current power usage, temperature and other conditions |

* [[State of power]] (SoP), the amount of power available for a defined time interval given the current power usage, temperature and other conditions |

||

* State of |

* State of safety (SOS) |

||

* Maximum charge current as a |

* Maximum charge current as a charge current limit(CCL) |

||

* Maximum discharge current as a [[discharge current limit]] (DCL) |

* Maximum discharge current as a [[discharge current limit]] (DCL) |

||

* Energy |

* Energy delivered since last charge or charge cycle |

||

* Internal impedance of a cell (to determine open circuit voltage) |

* Internal impedance of a cell (to determine open circuit voltage) |

||

* Charge |

* Charge delivered or stored (sometimes this feature is called ''[[coulomb]] counting'') |

||

* Total operating time since first use |

* Total operating time since first use |

||

* Total number of cycles |

* Total number of cycles |

||

* Temperature |

* Temperature monitoring |

||

* Coolant flow for air or liquid cooled batteries |

* Coolant flow for air or liquid cooled batteries |

||

| Line 50: | Line 51: | ||

* Different types of [[serial communications]]. |

* Different types of [[serial communications]]. |

||

* [[CAN bus]] communications, commonly used in automotive environments. |

* [[CAN bus]] communications, commonly used in automotive environments. |

||

* Different types of [[wireless communications]].<ref>{{cite web| |

* Different types of [[wireless communications]].<ref>{{cite web|author=Marius Valle |url=http://www.tu.no/artikler/kapper-ledninger-for-a-gi-lengre-rekkevidde-til-elbiler/364661 |title=Kapper ledninger for å gi lengre rekkevidde til elbiler|work=[[Teknisk Ukeblad]] |language=NO |date=19 November 2016|access-date=20 November 2016}}</ref> |

||

Low |

Low-voltage centralized BMSes mostly do not have any internal communications. |

||

Distributed or modular |

Distributed or modular BMSes must use some low-level internal cell–controller (modular architecture) or controller–controller (distributed architecture) communication. These types of communications are difficult, especially for high-voltage systems. The problem is voltage shift between cells. The first cell ground signal may be hundreds of volts higher than the other cell ground signal. Apart from software protocols, there are two known ways of hardware communication for voltage shifting systems, [[Opto-isolator|optical-isolator]] and [[Wireless communications|wireless communication]]. Another restriction for internal communications is the maximum number of cells. For modular architecture most hardware is limited to maximum 255 nodes. For high-voltage systems the seeking time of all cells is another restriction, limiting minimum bus speeds and losing some hardware options. Cost of modular systems is important, because it may be comparable to the cell price.<ref>{{cite web|url=http://lianinno.com/battery-management-systems/|title=Different Battery Management System Topology|access-date=6 December 2021|archive-date=2020-10-22 |archive-url=https://web.archive.org/web/20201022211627/http://lianinno.com/battery-management-systems/|url-status=dead}}</ref> Combination of hardware and software restrictions results in a few options for internal communication: |

||

* Isolated serial communications |

* Isolated serial communications |

||

* |

* Wireless serial communications |

||

To bypass power limitations of existing USB cables due to heat from electric current, communication protocols implemented in [[mobile phone charger]]s for negotiating an elevated voltage have been developed, the most widely used of which are [[Qualcomm Quick Charge]] and [[MediaTek Pump Express]]. "[[VOOC]]" by Oppo (also branded as "Dash Charge" with "OnePlus") increases the current instead of voltage with the aim to reduce heat produced in the device from internally converting an elevated voltage down to the battery's terminal charging voltage, which however makes it incompatible with existing USB cables and relies on special high-current USB cables with accordingly thicker copper wires. More recently, the [[USB Power Delivery]] standard aims for a universal negotiation protocol across devices of up to 240 watts.<ref> |

To bypass power limitations of existing USB cables due to heat from electric current, communication protocols implemented in [[mobile phone charger]]s for negotiating an elevated voltage have been developed, the most widely used of which are [[Qualcomm Quick Charge]] and [[MediaTek Pump Express]]. "[[VOOC]]" by Oppo (also branded as "Dash Charge" with "OnePlus") increases the current instead of voltage with the aim to reduce heat produced in the device from internally converting an elevated voltage down to the battery's terminal charging voltage, which however makes it incompatible with existing USB cables and relies on special high-current USB cables with accordingly thicker copper wires. More recently, the [[USB Power Delivery]] standard aims for a universal negotiation protocol across devices of up to 240 watts.<ref>{{Cite web|author=Sumukh Rao|url=https://techpp.com/2020/04/09/qualcomm-quick-charge-vs-oneplus-warp-charge-vs-oppo-vooc-vs-usb-pd/|title=Qualcomm Quick Charge vs OnePlus Warp Charge vs Oppo VOOC vs USB-PD – Battle of the fast charging technologies|website=TechPP|date=9 April 2020|access-date=6 December 2021}}</ref> |

||

=== Protection === |

=== Protection === |

||

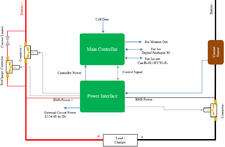

[[File:Bms MainController.png|thumb|BMS main controller|225x225px]] |

|||

A BMS may protect its battery by preventing it from operating outside its [[safe operating area]], such as:{{citation needed|date=May 2019}} |

A BMS may protect its battery by preventing it from operating outside its [[safe operating area]], such as:{{citation needed|date=May 2019}} |

||

| Line 77: | Line 79: | ||

* Including an internal [[switch]] (such as a [[relay]] or [[mosfet]]) which is opened if the battery is operated outside its safe operating area |

* Including an internal [[switch]] (such as a [[relay]] or [[mosfet]]) which is opened if the battery is operated outside its safe operating area |

||

* |

* Asking the devices to reduce or even stop using or charging the battery. |

||

* Actively controlling the environment, such as through heaters, fans, air conditioning or liquid cooling |

* Actively controlling the environment, such as through heaters, fans, air conditioning or liquid cooling |

||

* Reduce processor speed to reduce heats. |

|||

=== Battery connection to load circuit === |

=== Battery connection to load circuit === |

||

| Line 86: | Line 89: | ||

=== Balancing === |

=== Balancing === |

||

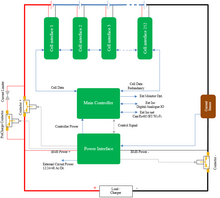

[[File:InnoTeg.png|thumb|Distributed |

[[File:InnoTeg.png|thumb|Distributed battery management system|221x221px]]In order to maximize the battery's capacity, and to prevent localized under-charging or over-charging, the BMS may actively ensure that all the cells that compose the battery are kept at the same voltage or State of Charge, through balancing. The BMS can balance the cells by: |

||

* Wasting [[energy]] from the most charged cells by connecting them to a [[Electrical load|load]] (such as through passive [[Battery regulator|regulators]]) |

* Wasting [[energy]] from the most charged cells by connecting them to a [[Electrical load|load]] (such as through passive [[Battery regulator|regulators]]) |

||

| Line 93: | Line 96: | ||

== Topologies == |

== Topologies == |

||

[[File:InnoCab.png|thumb|Cable |

[[File:InnoCab.png|thumb|Cable data transfer module]] |

||

[[File:Innoles.png|thumb|BMS |

[[File:Innoles.png|thumb|BMS wireless communication]] |

||

BMS technology varies in complexity and performance: |

BMS technology varies in complexity and performance: |

||

*Simple passive regulators achieve balancing across batteries or cells by bypassing charging current when the cell's voltage reaches a certain level. The cell voltage is a poor indicator of the cell's SoC (and for certain lithium chemistries, such as [[lithium iron phosphate battery|{{chem|LiFePO|4}}]], it is no indicator at all), thus, making cell voltages equal using passive regulators does not balance SoC, which is the goal of a BMS. Therefore, such devices, while certainly beneficial, have severe limitations in their effectiveness. |

*Simple passive regulators achieve balancing across batteries or cells by bypassing charging current when the cell's voltage reaches a certain level. The cell voltage is a poor indicator of the cell's SoC (and for certain lithium chemistries, such as [[lithium iron phosphate battery|{{chem|LiFePO|4}}]], it is no indicator at all), thus, making cell voltages equal using passive regulators does not balance SoC, which is the goal of a BMS. Therefore, such devices, while certainly beneficial, have severe limitations in their effectiveness. |

||

| Line 127: | Line 130: | ||

{{Authority control}} |

{{Authority control}} |

||

[[Category:Rechargeable batteries]] |

|||

[[Category:Energy conversion]] |

[[Category:Energy conversion]] |

||

[[Category:Battery charging]] |

[[Category:Battery charging]] |

||

This article needs additional citations for verification. Please help improve this articlebyadding citations to reliable sources. Unsourced material may be challenged and removed.

Find sources: "Battery management system" – news · newspapers · books · scholar · JSTOR (February 2024) (Learn how and when to remove this message) |

Abattery management system (BMS) is any electronic system that manages a rechargeable battery (cellorbattery pack), such as by protecting the battery from operating outside its safe operating area[clarification needed], monitoring its state, calculating secondary data, reporting that data, controlling its environment, authenticating it and / or balancing it.[1] Protection circuit module (PCM) is a simpler alternative to BMS.[2] A battery pack built together with a battery management system with an external communication data bus is a smart battery pack. A smart battery pack must be charged by a smart battery charger.[citation needed]

A BMS may monitor the state of the battery as represented by various items, such as:

Battery thermal management systems can be either passive or active, and the cooling medium can either be air, liquid, or some form of phase change. Air cooling is advantageous in its simplicity. Such systems can be passive, relying only on the convection of the surrounding air, or active, using fans for airflow. Commercially, the Honda Insight and Toyota Prius both use active air cooling of their battery systems.[3] The major disadvantage of air cooling is its inefficiency. Large amounts of power must be used to operate the cooling mechanism, far more than active liquid cooling.[4] The additional components of the cooling mechanism also add weight to the BMS, reducing the efficiency of batteries used for transportation.

Liquid cooling has a higher natural cooling potential than air cooling as liquid coolants tend to have higher thermal conductivities than air. The batteries can either be directly submerged in the coolant or coolant can flow through the BMS without directly contacting the battery. Indirect cooling has the potential to create large thermal gradients across the BMS due to the increased length of the cooling channels. This can be reduced by pumping the coolant faster through the system, creating a tradeoff between pumping speed and thermal consistency.[4]

Additionally, a BMS may calculate values based on the items listed below, such as:[citation needed]

The central controller of a BMS communicates internally with its hardware operating at a cell level, or externally with high level hardware such as laptops or an HMI.[clarification needed]

High level external communication are simple and use several methods:[citation needed]

Low-voltage centralized BMSes mostly do not have any internal communications.

Distributed or modular BMSes must use some low-level internal cell–controller (modular architecture) or controller–controller (distributed architecture) communication. These types of communications are difficult, especially for high-voltage systems. The problem is voltage shift between cells. The first cell ground signal may be hundreds of volts higher than the other cell ground signal. Apart from software protocols, there are two known ways of hardware communication for voltage shifting systems, optical-isolator and wireless communication. Another restriction for internal communications is the maximum number of cells. For modular architecture most hardware is limited to maximum 255 nodes. For high-voltage systems the seeking time of all cells is another restriction, limiting minimum bus speeds and losing some hardware options. Cost of modular systems is important, because it may be comparable to the cell price.[6] Combination of hardware and software restrictions results in a few options for internal communication:

To bypass power limitations of existing USB cables due to heat from electric current, communication protocols implemented in mobile phone chargers for negotiating an elevated voltage have been developed, the most widely used of which are Qualcomm Quick Charge and MediaTek Pump Express. "VOOC" by Oppo (also branded as "Dash Charge" with "OnePlus") increases the current instead of voltage with the aim to reduce heat produced in the device from internally converting an elevated voltage down to the battery's terminal charging voltage, which however makes it incompatible with existing USB cables and relies on special high-current USB cables with accordingly thicker copper wires. More recently, the USB Power Delivery standard aims for a universal negotiation protocol across devices of up to 240 watts.[7]

A BMS may protect its battery by preventing it from operating outside its safe operating area, such as:[citation needed]

The BMS may prevent operation outside the battery's safe operating area by:

A BMS may also feature a precharge system allowing a safe way to connect the battery to different loads and eliminating the excessive inrush currents to load capacitors.

The connection to loads is normally controlled through electromagnetic relays called contactors. The precharge circuit can be either power resistors connected in series with the loads until the capacitors are charged. Alternatively, a switched mode power supply connected in parallel to loads can be used to charge the voltage of the load circuit up to a level close enough to battery voltage in order to allow closing the contactors between battery and load circuit. A BMS may have a circuit that can check whether a relay is already closed before precharging (due to welding for example) to prevent inrush currents to occur.

In order to maximize the battery's capacity, and to prevent localized under-charging or over-charging, the BMS may actively ensure that all the cells that compose the battery are kept at the same voltage or State of Charge, through balancing. The BMS can balance the cells by:

BMS technology varies in complexity and performance:

BMS topologies fall in three categories:

Centralized BMSs are most economical, least expandable, and are plagued by a multitude of wires. Distributed BMSs are the most expensive, simplest to install, and offer the cleanest assembly. Modular BMSes offer a compromise of the features and problems of the other two topologies.

The requirements for a BMS in mobile applications (such as electric vehicles) and stationary applications (like stand-by UPSes in a server room) are quite different, especially from the space and weight constraint requirements, so the hardware and software implementations must be tailored to the specific use. In the case of electric or hybrid vehicles, the BMS is only a subsystem and cannot work as a stand-alone device. It must communicate with at least a charger (or charging infrastructure), a load, thermal management and emergency shutdown subsystems. Therefore, in a good vehicle design the BMS is tightly integrated with those subsystems. Some small mobile applications (such as medical equipment carts, motorized wheelchairs, scooters, and fork lifts) often have external charging hardware, however the on-board BMS must still have tight design integration with the external charger.

Various battery balancing methods are in use, some of them based on state of charge theory.